OEM refers to the production, commonly known as "OEM", for the brand. It can only use the brand name after production, and can not be produced with its own name.

ODM is provided by the manufacturer. After the brand owner takes the look, they attach the name of the brand owner for production and sales. If the brand owner does not buy the copyright, the manufacturer has the right to reproduce itself, as long as the tag does not have the brand owner's logo.

The main difference between ODM and OEM: OEM is the product design scheme proposed by the client and enjoys the copyright —— No matter who completes the overall design, the principal shall not provide the designed product for a third party; while ODM is completed by the manufacturer itself and purchased by the OEM after the product is formed.

OEM OEM advantages:

1. Cost reduction: OEM OEM can help companies reduce production costs because OEM can provide efficient production lines and technical support to avoid quality problems in multi-production and reduce the cost of manufacturing products. At the same time, the smaller the unit price and cost of production, the factory can have a stronger bargaining power, can press the price of raw materials and packaging materials to the lowest, brand owners can obtain products at a lower price, increase their own profits, so that the enterprise assets can be effectively utilized.

2. Improve efficiency: OEM OEM can improve production efficiency because OEM can produce products quickly based on the requirements of production orders.

3. Increase product quality: OEM OEM processors usually have rich production experience and technical knowledge, which can ensure the quality of products.

4.Risk reduction: OEM OEM can reduce production risk because OEM OEM are responsible for production and quality control.

5. Focus on product research and development, and provide competitiveness:

It is conducive to brand owners to deal with the problem of unsalable products due to changes in market demand, and to maintain their own enterprise characteristics and to help brand owners to increase their competitiveness.

6. Rich management experience and improve enterprise efficiency:

It is conducive to brand owners to deal with the problem of unsalable products due to changes in market demand, and to maintain their own enterprise characteristics and to help brand owners to increase their competitiveness.

Notes for OEM processing:

1. Brand image: OEM products will be the brand of OEM, not the brand of the company, so please make sure that the brand image of OEM is consistent with the brand image of the company.

2. Quality control: Please ensure that the OEM can provide sufficient quality control assurance to ensure product quality.

3.Intellectual Property rights: Please ensure that the company's intellectual property rights are protected to prevent the substitute processors from using the company's technology and design in the future.

The advantages of choosing an OEM / ODM

1. Save repeated investment for the entire industry: an OEM can start to process business for investors in different regions of the same industry. In addition, according to the specific requirements of each customer order, to provide exclusive product customized production. The cost of building a similar production line per customer is greatly reduced. Of course, it does not exclude the negative effects of similar business competition between OEM enterprises.

2. Threshold for building independent copyright products: no need to build factories, no need to purchase equipment, no need to spend energy and time for relevant production qualifications, and only need to have a relatively formed idea of the product. Professional OEM processing enterprises will complete the formal products through supporting scientific research and production services. Undoubtedly, it provides opportunities for small and micro investors with limited OEM project budget.

A product, designed and manufactured, is separate and needs to be done in atively. During the information communication between designer and manufacturer, sample confirmation and product acceptance. Any link of the problems, will affect the quality of the product. So it is good for food and health care products, or clothing, or electronic products. No matter which industry, and cooperation with manufacturers need to process the key points.as follows:

1. Cooperation conditions: to ensure the regular products.

2. Bidding procedure: that is, the commission processing contract signed by both parties, the labeling of products, materials, costs, construction period and other information must be clear, so as not to be unhappy in the later period. Mainly is to ensure the smooth OEM processing, a constraint on the other side.

3. Quality quality: Of course, the commissioner wants to monitor the OEM production of their products through various methods. In response, the producers use the labeled production process, but they will also provide live video of key links or trilogy tests to reassure customers.

The cooperation with OEM / ODM company is a mutually beneficial cooperation for either party. Choosing a good OEM / ODM company for cooperation, it is no doubt the icing on the cake for the development of its own company.

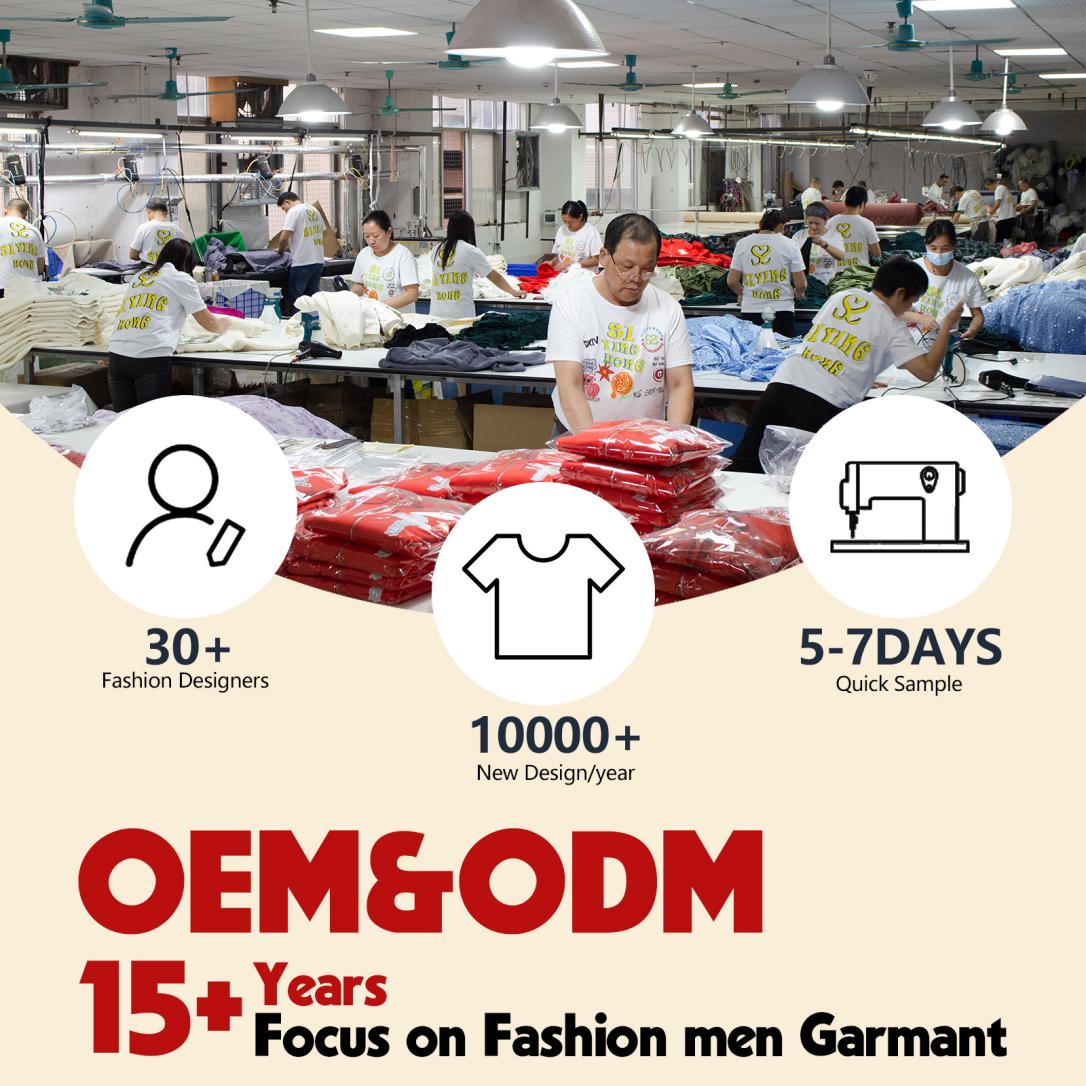

Siyinghong Is a company, focus on clothing OEM / ODM, strict selection of high-quality raw materials, professional team, many years of industry export experience, for you to create your own clothing brand.

Post time: Dec-22-2023