Screen printing refers to the use of screen as a plate base, and through the photosensitive plate making method, made with pictures screen printing plate. Screen printing consists of five elements, screen plate, scraper, ink, printing table and substrate. Screen printing is one of the most important forms of artistic creation.

1. What is screen printing

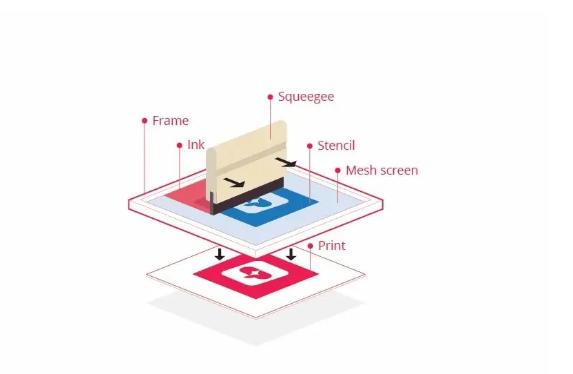

Screen printing is the process of transferring a stencil design onto a flat surface using screen, ink, and scraper. Fabric and paper are the most common surfaces for screen printing, but using specialized inks, it is also possible to print on wood, metal, plastic and even glass. The basic method involves creating a mold on a fine mesh screen and then threading ink (or paint, in the case of artwork and posters) through it to imprint the design on the surface below.

The process is sometimes called "screen printing" or "screen printing," and although the actual printing process is always very similar, the way the stencil is created can vary, depending on the material used. Different template techniques include:

Set ape or vinyl to cover the desired area of the screen.

Use a "screen blocker" such as glue or paint to paint the mold onto the grid.

Create a stencil using a photographic emulsion, and then develop the stencil in a similar way to a photo (you can learn more about this in the step-by-step guide).

Designs made using screen printing techniques may use only one or a few inks. For multi-colored items, each color must be applied in a separate layer and a separate template used for each ink.

2. Why use screen printing

One of the reasons screen printing technology is so widely used is because it produces vibrant colors even on darker fabrics. The ink or paint is also located in multiple layers on the surface of the fabric or paper, thus giving the printed piece a satisfactory touch.

The technology is also favored because it allows pri nters to easily copy designs multiple times. Since the design can be copied over and over again using the same mold, it is useful for creating multiple copies of the same garment or accessory. When operated by an experienced printer using professional equipment, it is also possible to create complex color designs. While the complexity of the process does mean that the number of colors a printer can use is limited, it does have more intensity than what can be achieved using digital printing alone.

Screen printing is a popular technique among artists and designers due to its versatility and ability to reproduce vivid colors and clear images. In addition to Andy Warhol, other artists known for their use of screen printing include Robert Rauschenberg, Ben Shahn, Eduardo Paolozzi, Richard Hamilton, RB Kitaj, Henri Matisse and Richard Estes.

3. Screen printing process steps

There are different methods of screen printing, but they all involve the same basic techniques. The form of printing we will discuss below uses a special light-reactive emulsion to create custom stencils; Because it can be used to make complex stencils, it tends to be the most popular type of commercial printing.

Step 1: The design is created

First, the printer takes the design they want to create on the final product, and then prints it onto a transparent acetic acid film. This will be used to create the mold.

Step 2: Prepare the screen

Next, the printer selects a mesh screen to suit the complexity of the design and the texture of the printed fabric. The screen is then coated with a photoreactive emulsion that hardens when developed under bright light.

Step 3: Expose the lotion

An acetate sheet with this design is then placed on an emulsion-coated screen and the entire product is then exposed to very bright light. The light hardens the emulsion, so the part of the screen covered by the design remains liquid.

If the final design will contain multiple colors, a separate screen must be used to apply each layer of ink. To create multi-color products, the printer must use his skills to design each template and align them perfectly to ensure that the final design is seamless.

Step 4: Wash off the emulsion to form a stencil

After exposing the screen for a certain amount of time, areas of the screen that are not covered by the design will harden. Then carefully rinse off all unhardened lotion. This leaves a clear imprint of the design on the screen for the ink to pass through.

The screen is then dried and the printer will make any necessary touches or corrections to make the imprint as close to the original design as possible. Now you can use the mold.

Step 5: The item is ready to print

The screen is then placed on the press. The item or garment to be printed is placed flat on a printing plate below the screen.

There are many different printing presses, both manual and automatic, but most modern commercial printing presses will use a self-rotating rotary disk press, as this allows several different screens to be run simultaneously. For color printing, this printer can also be used to apply individual layers of color in quick succession.

Step 6: Press ink through the screen onto the item

The screen drops to the printed board. Add the ink to the top of the screen and use the absorbent scraper to pull the ink along the entire length of the screen. This presses the ink over the open area of the template, thereby embossing the design onto the product below.

If the printer is creating multiple items, raise the screen and place the new clothes on the printing plate. Then repeat the process.

Once all items have been printed and the template has served its purpose, a special cleaning solution can be used to remove the emulsion so that the screen can be reused to create a new template.

Step 7: Dry the product, check and finish

The printed product is then passed through a dryer, which "cures" the ink and produces a smooth, non-fading surface effect. Before the final product is passed on to the new owner, it is inspected and thoroughly cleaned to remove all residues.

4. Screen printing tools

In order to get clean, clear prints, screen presses need to have the right tools to complete the job. Here, we will discuss each screen printing device, including the role they play in the printing process.

| screen printing machine |

Although it is possible to screen print using only mesh mesh and a squeegee, most printers prefer to use a press because it allows them to print many items more efficiently. This is because the printing press holds the screen in place between prints, making it easier for the user to change the paper or clothing to be printed.

There are three types of printing presses: manual, semi-automatic and automatic. Hand presses are manually operated, which means they are very laborious. Semi-automatic presses are partially mechanized, but still require human input to exchange pressed items, while automatic presses are fully automated and require little input.

Businesses that require a large number of printing projects often use semi-automatic or fully automatic presses because they can print faster, more efficiently and with minimal errors. Smaller companies or companies that use screen printing as a hobby may find manual desktop presses (sometimes referred to as "hand" presses) better suited to their needs.

| ink |

Ink, pigment, or paint is pushed through the mesh screen and into the item to be printed, transferring the color imprint of the stencil design onto the product.

Choosing ink is not just about choosing color, there are many more options. There are many professional inks that can be used to produce different effects on the finished product. For example, printers can use flash inks, deformed inks, or puffed inks (which expand to form a raised surface) to produce a unique look. The printer will also consider the fabric type of screen printing, as some inks are more effective on some materials than others.

When printing clothing, the printer will use an ink that is machine washable after being heat-treated and cured. This will result in non-fading, long-term wearing items that can be worn again and again.

| screen |

The screen in screen printing is a metal or wooden frame covered with fine mesh fabric. Traditionally, this mesh was made of silk thread, but today, it has been replaced by polyester fiber, which provides the same performance at a lower price. The thickness and thread number of the mesh can be selected to suit the surface to be printed or the texture of the fabric, and the spacing between the lines is small, so that more details can be obtained in the printing.

After the screen is coated with emulsion and exposed, it can be used as a template. After the screen printing process is complete, it can be cleaned and reused.

| scraper |

A scraper is a rubber scraper attached to a wooden board, metal or plastic handle. It is used to push the ink through the mesh screen and onto the surface to be printed. Printers often choose a scraper that is similar in size to the screen frame because it provides better coverage.

The harder rubber scraper is more suitable for printing complex designs with many details, as it ensures that all corners and gaps in the mold absorb a layer of ink evenly. When printing less detailed designs or printing on fabric, a softer, more yielding rubber scraper is often used.

| Cleaning station |

The screens need to be cleaned after use to remove all traces of the emulsion, so they can be used again for later printing. Some larger printing houses may use vats of special cleaning fluid or acid to remove the emulsion, while others only use a sink or sink and power hose to clean the screen.

5.Will screen printing ink wash away?

If the garment has been properly screen printed by a trained professional using heat-treated washable ink, the design should not be washed out. In order to ensure that the color does not fade, the printer needs to ensure that the ink has been set according to the manufacturer's guidelines. The correct drying temperature and time depends on the type of ink and the fabric used, so the instructions need to be followed if the printer is going to create a long-lasting washable item.

6. What is the difference between screen printing and digital printing?

Direct ready-to-wear (DTG) digital printing uses a dedicated fabric printer (somewhat like an inkjet computer printer) to transfer images directly onto textiles. It differs from screen printing in that a digital printer is used to transfer the design directly onto the fabric. Because there is no stencil, multiple colors can be applied at the same time, rather than having to apply multiple colors in a separate layer, which means that the technique is often used to print complex or very colorful designs.

Unlike screen printing, digital printing requires almost no setup, which means digital printing is a more cost-effective option when printing small batches of clothing or single items. And because it uses computer images instead of templates, it's perfect for making photography or highly detailed designs. However, because the color is printed using CMYK style color dots rather than pure color ink, it cannot provide the exact same color intensity as screen printing. You also can't use a digital printer to create textured effects.

Siyinghong Garment Factory has 15 years of experience in clothing, and has 15 years of experience in the printing industry. We can provide professional logo printing guidance for your samples/bulk goods, and recommend suitable printing methods to make your samples/bulk goods more perfect. You can communicate with us immediately!

Post time: Dec-21-2023