The selection of dyeing and finishing process is mainly based on the variety, specifications and finished product requirements of the fabric, which can be divided into pre-treatment, dyeing, printing, post-finishing and so on.

Pre-treatment

Natural fibers contain impurities, in the textile processing process and add the slurry, oil and contaminated dirt, the existence of these impurities, not only hinder the smooth progress of dyeing and finishing processing, but also affect the wear performance of the fabric.

The purpose of pre-treatment is to apply chemical and physical mechanical action to remove impurities on the fabric, make the fabric white, soft, and have good permeability to meet the requirements of taking, and provide qualified semi-products for dyeing, printing and finishing.

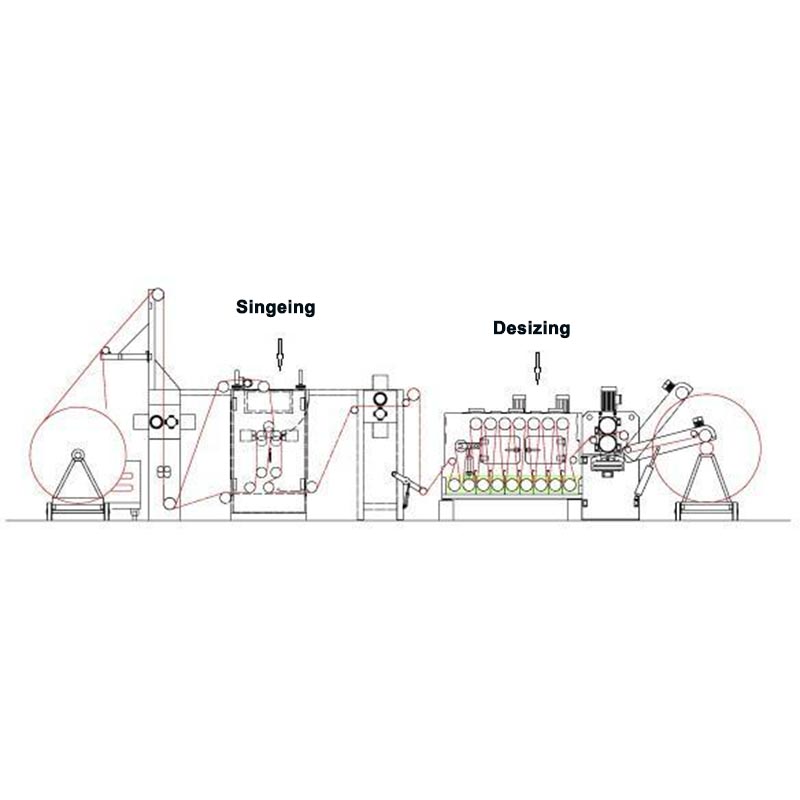

Cotton: raw cloth preparation, singeing, desizing, boiling, bleaching, mercerizing. Polyester: cloth preparation, refined (liquid alkali, etc.), preshrinking, reservation, alkali deweighting (liquid alkali, etc.).

Singeing

Usually, after entering the printing and dyeing factory from the textile mill, the grey cloth should first be inspected, turned over, batching, printing and sewing, and then singed.

Reasons:

(1) on the cloth not singeing down too much, different length;

(2) the degree of finish is poor, easy contamination;

(3) in the sequence zhongyi wool dyeing and finishing, printing and dyeing defects.

Singeing objective:

(1) improve cloth luster; Improve the finish;

(2) improve the pilling resistance (especially the chemical fiber fabric);

(3) improve the style, singeing can make fabric becomes crisp, were bone.

Desizing

In the weaving process, the warp is subjected to greater tension and friction, which is easy to break. In order to reduce warp breaking, improve weaving efficiency and grey fabric quality, it is necessary to sizing the warp yarn before weaving. The fiber in the yarn sticks and holds together, and forms a solid slurry film on the surface of the yarn, making the yarn tight and smooth, thus improving the breaking strength and wear resistance of the yarn.

Desizing purpose: After sizing, the slurry penetrates into the fibers and partly attaches to the surface of the warp. While improving the performance of the yarn, the slurry pollutes the dyeing and finishing processing fluid, hinders the chemical interaction between the fibers and dyeing and chemical materials, and makes it difficult to carry out dyeing and finishing processing.

(1) Introduction to commonly used slurry

Natural slurry: starch, seaweed gum, gum, etc.

Starch properties:

① in the case of acid decomposition;

② in the case of alkali stability, swelling;

③ in the case of oxidants can be decomposed;

④ by the starch decomposition enzyme decomposition.

Chemical slurry: cellulose derivatives such as hydroxymethylcellulose (CMC), polyvinyl alcohol (PVA), polyacrylic acid, polyester, etc.

PVA properties:

① stable to acid and base, viscosity does not reduce;

② It is degraded by oxidant.;

③ Wide applicability, good compatibility, no mixing reaction

(2) Commonly used desizing methods

1. Alkaline desizing

One of the most widely used methods in domestic dyeing plants, but the desizing rate is not high, and other impurities can be removed while desizing.

Mechanism: The use of sodium hydroxide dilute solution treatment, starch slurry under the action of alkali swelling (or swelling) phenomenon, does not occur chemical reaction, so that the slurry from gel to sol, reduce the binding force between the fiber and the slurry, and then the use of washing and mechanical force to remove it. For PVA and polyacrylate slurries, it is able to dissolve sodium hydroxide in dilute solutions.

(starch) enzyme desizing

Enzymes are also called enzymes, biocatalysts.

Features: high desizing rate, not injury fiber, only for starch, cannot remove impurities.

Features: a. High efficiency. b. Specificity: An enzyme can catalyze only one reaction or even a specific reaction. c. The activity is affected by temperature and PH value.

For starch slurries or starch mixed slurries (starch content is dominant), amylase can be used for desizing.

Acid desizing

Domestic application is not much, because the use is easy to damage the fiber, more combined with other methods. The two-step method is adopted: alkali desizing - acid desizing. Acid desizing can make starch hydrolyze, remove mineral salt and so on, and make up for each other.。

Oxidation desizing

Oxidizing agent: NaBrO2 (sodium bromite) H2O2, Na2S2O8, (NH4) 2S2O8, etc.

Principle: The oxidizing agent can oxidize and degrade all kinds of slurry, its molecular weight and viscosity are greatly reduced, the water solubility is increased, and the slurry is prevented from adhering to the fiber, and then the hydrolysate is removed by efficient washing.

(1) Boiling

The purpose of boiling is to remove fiber impurities and improve the processing properties of the fabric, especially the wettability.

Natural impurities: For pure cotton fabrics, mainly fiber co-organisms or associated organisms, including oil wax, pectin, protein, ash, pigment and cottonseed shells.

Artificial impurities: impurities such as oil, antistatic agent and oil, rust and residual slurry added in spinning and weaving processing.

These impurities seriously affect the wettability of the fabric and hinder the dyeing and finishing of the fabric, and must be removed in the scouring system with sodium hydroxide as the main and surfactants as the auxiliary.

(2) Bleaching

After boiling, most of the natural and artificial impurities on the fabric are removed, but for bleached and light-colored fabrics, bleaching is also required. That is to remove pigment, improve whiteness as the main purpose of bleaching processing.

Chemical fiber does not contain pigment, after boiling has been very white, and cotton fiber after scouring pigment still exists, the whiteness is poor, so bleaching is mainly for natural impurities on cotton fiber.

(3) Bleach

Oxidation type: sodium hypochlorite, hydrogen peroxide and sodium chlorite, etc., mainly used in cotton fiber and blended fabrics.

Reduced: NaHSO3 and insurance powder, etc., mainly used for protein fiber fabrics.

(4) Sodium hypochlorite bleaching:

Sodium hypochlorite bleaching is mostly used for bleaching cotton fabrics and cotton blended fabrics, and sometimes also used for bleaching polyester cotton blended fabrics. However, it can not be used for bleaching protein fibers such as silk and wool, because sodium hypochlorite has a destructive effect on protein fibers, and makes fibers yellowing and damage. In the bleaching process, in addition to the destruction of natural pigments, the cotton fiber itself may also be damaged, therefore, it is necessary to control the bleaching process conditions, so that the appearance quality and internal quality are qualified.

Sodium hypochlorite is easy to manufacture, low cost, sodium hypochlorite bleaching operation is convenient, simple equipment, but because sodium hypochlorite bleaching is bad for environmental protection, so it is gradually replaced by hydrogen peroxide.

(5) Hydrogen peroxide bleaching H2O2:

Hydrogen peroxide, also known as hydrogen peroxide, has the molecular formula H2O2. Hydrogen peroxide bleaching is called oxygen bleaching. The stability of hydrogen peroxide solution is very poor under alkaline conditions. As a result, commercial hydrogen peroxide is weakly acidic.

Fabric bleached with hydrogen peroxide has good whiteness, pure color, and is not easy to yellowing when stored. It is widely used in bleaching cotton fabric. Oxygen bleaching has greater adaptability than chlorine bleaching, but hydrogen peroxide is higher than sodium hypochlorite price, and oxygen bleaching requires stainless steel equipment, energy consumption is larger, the cost is higher than chlorine bleaching.

At present, the open-width steam bleaching method is used more in printing and dyeing factories. This method has high degree of continuity, automation and production efficiency, simple process flow and does not produce environmental pollution.

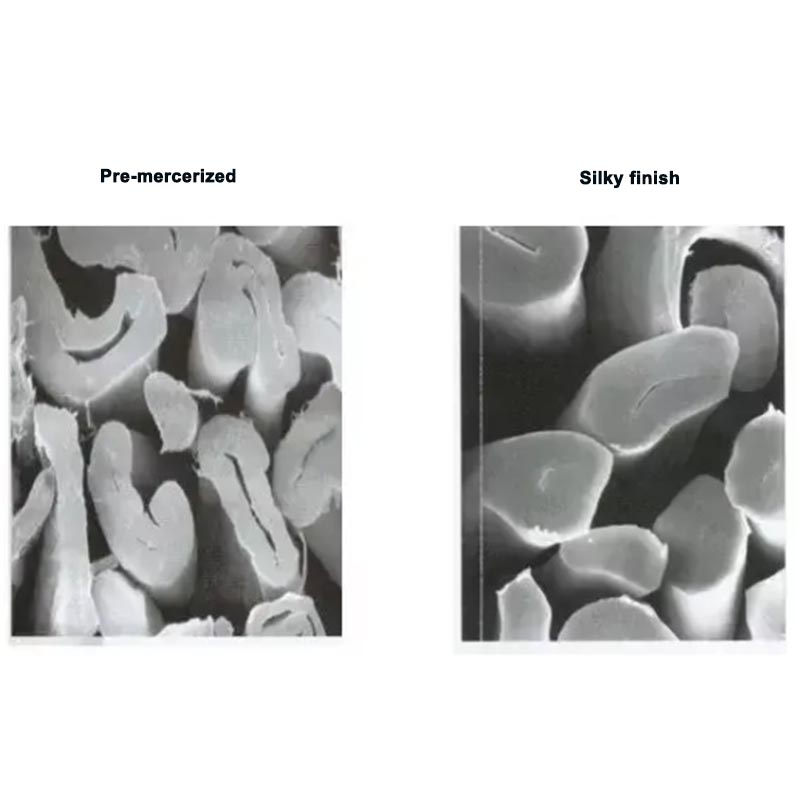

5. Mercerized (cotton fabric)

Textiles under a certain state of tension, with the help of concentrated caustic soda, and maintain the required size, can obtain a silky luster, this process is called mercerization.

(1) Purpose of mercerization:

A.Improve the surface gloss and feel of the fabric, due to the swelling of the fiber, the fiber arrangement is more orderly, and the reflection of light is more regular, thus improving the gloss.

B.Increase the rate of dyeing color after mercerizing finishing, fiber zone decreases, amorphous area increase, and dyes are more likely to enter the fibers, coloring rate than mercerized cotton fiber increased by 20%, and brilliance improved, at the same time increase the dead front covering power.

C.To improve dimensional stability mercerizing have finalize the design effect, can eliminate the rope wrinkles, more can meet the quality requirements of dyeing and printing half-and-half products. The most important thing is that after mercerizing, the stability of fabric expansion deformation has been greatly improved, thus greatly reducing the shrinkage rate of the fabric.

6. Refining, pre-shrinking (chemical fiber fabric)

The purpose of refining pre-shrinking is mainly to remove the oil, slurry and dirt adsorbated on the fabric (fiber) during weaving storage and transportation, and at the same time, some oligomers on the fiber can also be dissolved in high temperature refining. The grey cloth should be pre-shrunk before the amount of alkali, and the additives such as olein and caustic soda should be mainly added. Pretreatment of chemical fiber fabric is carried out in high temperature and high pressure dyeing machine.

7.Alkali reduction (chemical fiber fabric)

(1) Principle and effect of alkali reduction

Alkali reduction treatment is the process of treating polyester fabric in high temperature and concentrated burning lye. Polyester fiber is hydrolyzed and broken by ester bond of polyester molecular chain on the surface of the fiber in sodium hydroxide aqueous solution, and hydrolysis products with different polymerization degrees are continuously formed, and finally water-soluble sodium terephthalate and ethylene glycol are formed. Alkali reduction equipment mainly includes overflow dyeing machine, continuous reducing machine, intermittent reducing machine three kinds, except overflow dyeing machine; Continuous and intermittent reducing machines can recycle the remaining lye. In order to ensure the stability of the appearance shape and size of the grey cloth for some alkali reduction products, it is necessary to add a predetermined process, and then enter the dyeing process.

Post time: Feb-28-2025