All say Plate-making division Is to use CAD to draw a paper sample diagram, is too general. It is too one-sided to say that plate-making is just a drawing.

Lets first talk about the situation of domestic plate makers (incorrect welcome correction, because what I see is not necessarily all, the clothing industry is very big). According to the discussion should be cut (cut and sew) clothing plate maker, not including sweaters,Round machine, The plate-maker of the warp knitting machine. So only say cut and sew inside the plate maker, as to whether knitting or weaving here will not be separated, because they are to use cad drawing sample.

1. Plate maker

The name of the plate maker varies according to the local cultural differences,Paper Sample, Board makers, board makers, and so on are actually refer to the same person.

He is responsible for following the style requirements (either the designers requirements or his own ideas, because some plate makers are also responsible for the design of the clothes)

With the selected fabrics (if the clothing is designed by the designer, the fabric is usually selected by the designer)

Combined with the main size (because the model has not come out only a few main sizes, such as shoulder width, chest width, sleeve length, clothing length [these sizes are obtained by standardized dummy fitting dolls or real models] combined with fabric shrinkage rate, fabric characteristics, etc.)

Combined with their own experience knowledge (what seam method for each bone, how much bone stop, etc.)

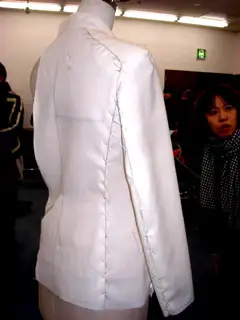

Cad out of the first round of the first paper sample, according to the paper cutting fabric to do the first round of board, and the designer on the dummy or model to try the effect, according to the requirements of the designer to do improvement, the basic powerful plate making division can make the clothes that meet the requirements of the second round. Some of the above links, or the plate maker itself lack of experience, resulting in poor sample effect (plate type, bone suture, clothing creativity, etc.); the board to change several rounds to barely achieve the effect; or some directly cancelled by the designer in the middle is encountered.

This process is a brief description, eliminating the development of surface accessories, printing embroidery development, color selection and so on.

2. Grade of the plate maker

Of course, the level of the maker, summarize the plate I met as follows,

The most elementary, basically is to draw the most basic style of the paper sample, probably outside some training class to learn a Clothing paper Courses, limited experience, limited creativity. The general majority processing of materials supplied by the foreign businessmen The factory like to use such a plate maker, because the labor is cheap, the work does not need any personal opinions, is to take the board to copy. Most of the treasure on the said is the original design is also useful to this level of plate maker, buy big brand clothes, directly change something to make when their own original design. Among them, there is no lack of some students just graduated but lack of practical experience of children, here is also good. At that time, I worked in a large company and contacted a German who had just graduated from German garment engineering to make paper samples. At the beginning, I often made some mistakes, such as the difference of the fabric, the shrinkage rate, sometimes mixing the shrinkage rate pattern, the bone position, and the choice of the bone seam did not consider the characteristics of the fabric...

Intermediate level, good understanding ability, rich experience, understand a targeted foreign language. Understand the foreign language mainly with their own designer partner barrier-free, easy to understand the designer. General big name designer love to use such board division, because some designers she really do not understand the paper sample car seam these... There is still a shortage of such people, and many big companies are hiring these people.

Advanced, can design clothes, creative and ideas, understand the sample design and development of car seam, understand the foreign language (the most basic English). Basically these people can do the big technical director of clothing development.

3. Talk about the difficulty of making plates

- ·The version that everyone cares about

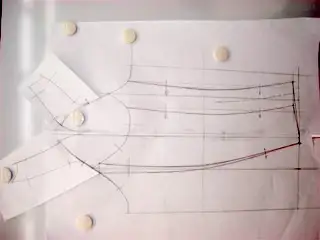

Actually version on the paper, a basic concept is the clothes split for the cut, the size of each parts of the body reflected in a single cut or combination cut (close or loose effect, stick more loose, what kind of comfortable, wearing habits to consider), each size can be seen as a point, and then use a straight line or arc connect point. How the arc changes in each part of the body.

As a new version, the effect of the standardized dummy and the effect of the real person have to improve, whether to join the discussion, whether the different fabrics need sample wear test (wear testing). For a large company, there is a lot to do, such as the difference of people in different countries and regions, because a model may make millions of clothes a year to sell around the world.

For some lax companies, usually consider less, so often many people complain about the version of the problem. For example, the boss bought a European version of the clothes to copy for the version division, do not consider the difference of human figure, also do not consider the wearing habits of people in different regions to copy the original version, the effect can be imagined.

As an old version, what is the market feedback, whether to need further adjustment, etc.

- ·Modification of the template

The money that cooperates with stylist, must look at the stylist to some model trial body comment to modify sample.

For example, some size of the modification, where more cloth, whether the model skeleton is strange caused by certain conventional size is not applicable to how to modify.

or example, some modifications of workmanship, the fabric characteristics not considered in the early stage lead to bone position yarn, bone position twisting, shrinkage of clothes caused by how to modify.

For example, some special cutting decoration modification and so on many and their own experience knowledge to improve, the book knowledge is too limited.

- ·Number of cuts

Because common for most people, ordinary zippered jackets, T-shirts, jumpers, and long skirts are some regular styles, the number of cut pieces is not too much including a suit. But some special or complex styles, the number of pieces is amazing, some outdoor function clothes are always more than 100 pieces of pieces, some together with the liner can cut 200 pieces...

4. With the development of computers, there are also a lot of convenience, such as basic paper samples, now many paper sample systems developed based on CAD are integrated with a variety of two basic paper samples, the input size can be out of the corresponding paper sample. For example, put the code, very early had a computer put the code, input the formula, the computer automatically complete the other sizes of the paper sample. For example, row rack / discharge material, now basically computer automatic row.

And then there are relatively new ones, which are similar VR technology The plate making. After scanning the models body, the size of the parts, the clothes. According to the data, the plate maker issued a base code paper sample on the system, combined with the scanned fabric applied to the scanned body of the scanned model. The system identifies the test condition of each part with color. Is it too loose or too tight, and whether the suture and turning corners are round or smooth. Finally, the modified virtual clothes with some accessories can get a shadow version (photo shooting sample), so for modern plate makers, to jump to a big company, your computer technology is also demanding.

Post time: Dec-30-2024