Pleats can be divided into four common forms: pressed pleats, pulled pleats, natural pleats, and plunging pleats.

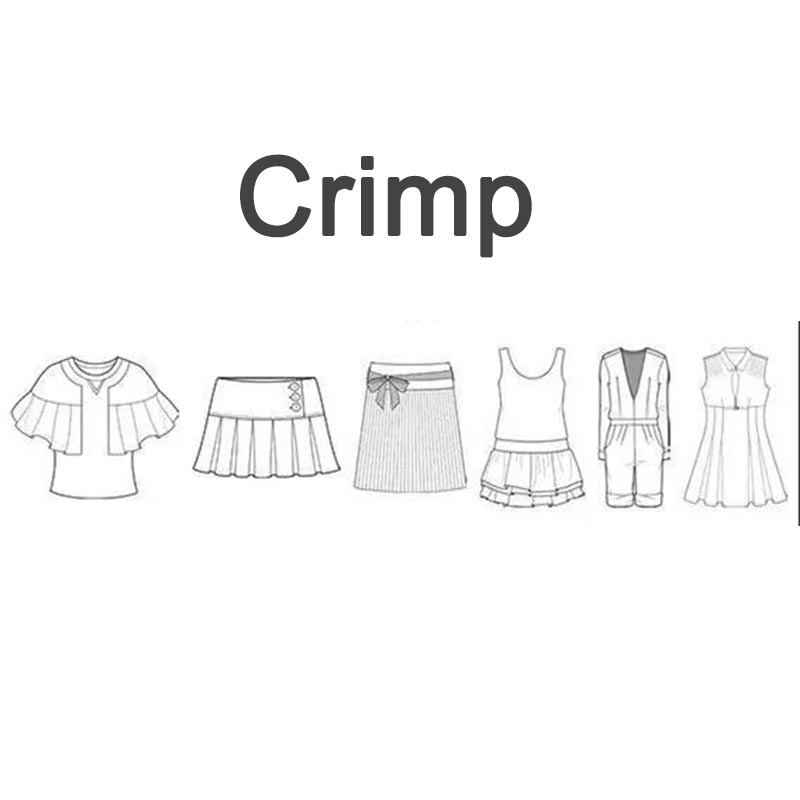

1.Crimp

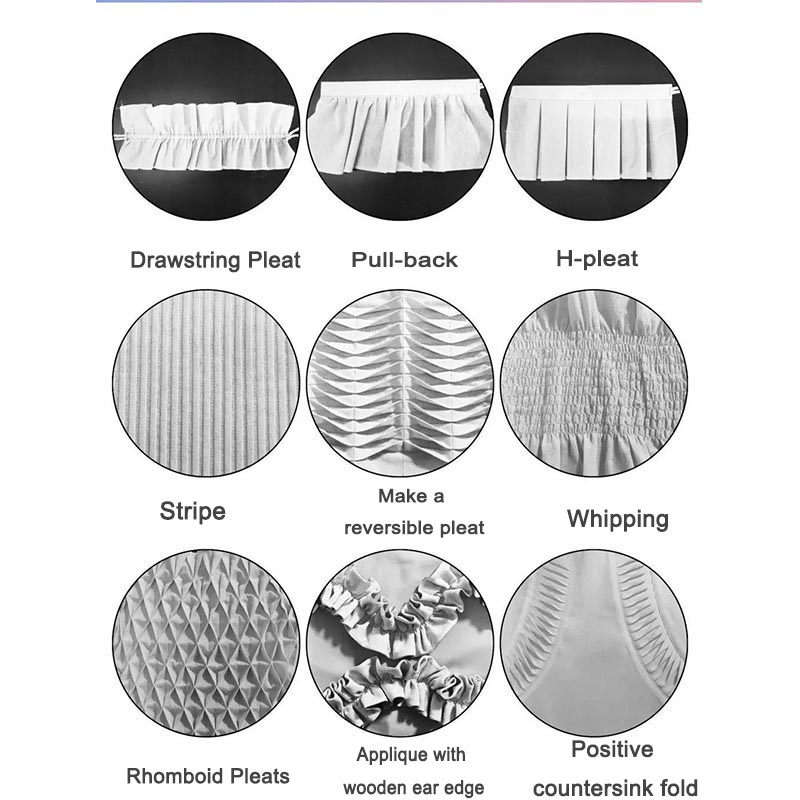

Crimp is also known as ironing pleat, folding pleat, it is the fabric in the form of creasing or overlapping, press molding with machine, can also be sewn with machine thread. Continuous pleats are mostly used for decoration, or groups, or individual pleats, such pleats have a regular and neat visual effect, giving a sense of order, especially straight pleats, pleats repeated and regular, easy to form a regular, strong feeling. In the way of forming the pleat, it is generally fixed at one end of the pleat, while the other end moves naturally in a specific direction, showing the contrast style and movement characteristics of the dynamic and static, flat and undulating, compact and stretched pleat. Common forms of pleats are parallel pleats and row pleats (there are along pleats and inverted pleats in some places called knife pleats), on pleats (there are live pleats and dead pleats), I-pleats (there are internal pleats and external pleats), line pleats, cross pleats, etc. Special pleats series are: organ pleats, I-word pleats, toothpick pleats, row pleats, wave pleats, bamboo leaf pleats, sun pleats, hand pleats, random pleats, corn pleats and so on.

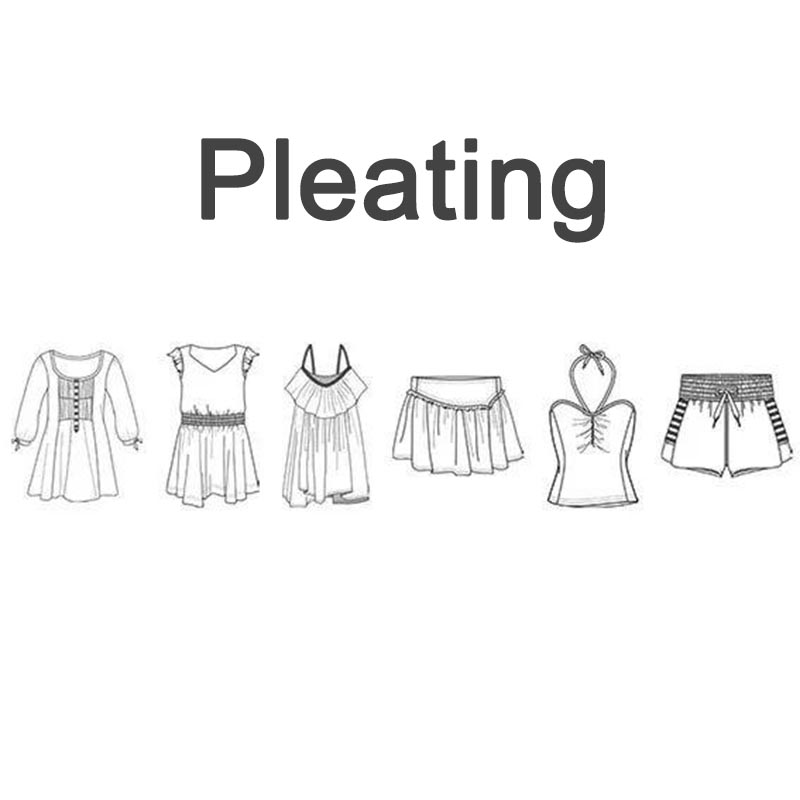

2.Pleats

Drawing pleats, also known as broken pleats, pleats with points or lines as a unit, is a natural, rich and irregular pleating state formed by fabric gathering contraction or tightening. The multidirectional pleats are mostly pleated in units of points, with strong directivity, and the pleats are radially textured. From the point of view of the process, it can be used to sew the machine line on the fabric, and the machine line can be drawn to form a pleating, or a few lines of elastic line can be stitched, and the natural pleating will be formed according to the elastic effect. Pleating is suitable for light fabric, controlling fullness in width to produce decorative effect, usually used in children's wear, maternity wear and decorated lively women's wear.

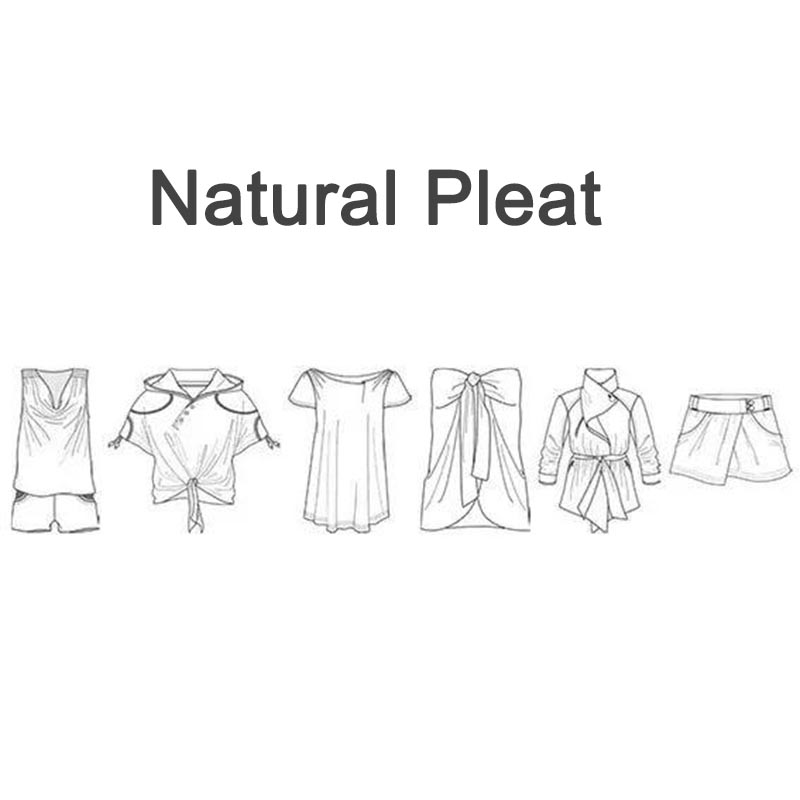

3.Natural pleats

Natural pleats, also known as live pleats, are pleated within the specified range and piled up from different directions, and the fabric presents a thick, vivid and gorgeous texture state. Natural pleats have flexibility in form, kneading, superimposing or stacking the fabric in an orderly or random manner. This effect is attached to the human body, which will produce a visual effect on the shape and form a smooth arc in the appearance. The shape of this kind of pleats is varied, natural and random, and full of rhythm. The gathering effect of natural pleats is very obvious, which can produce a feeling of concentration, thick and expansion to achieve the purpose of emphasizing, highlighting and exaggerating in clothing. Natural pleats also help to highlight the chest, tighten the waist, expand the buttocks, increase the amount of activity in a certain part of the function, such as the crotch of Haren pants. Natural pleats are commonly used in places such as pendant collars, wavy pleats on women's dresses and evening dresses.

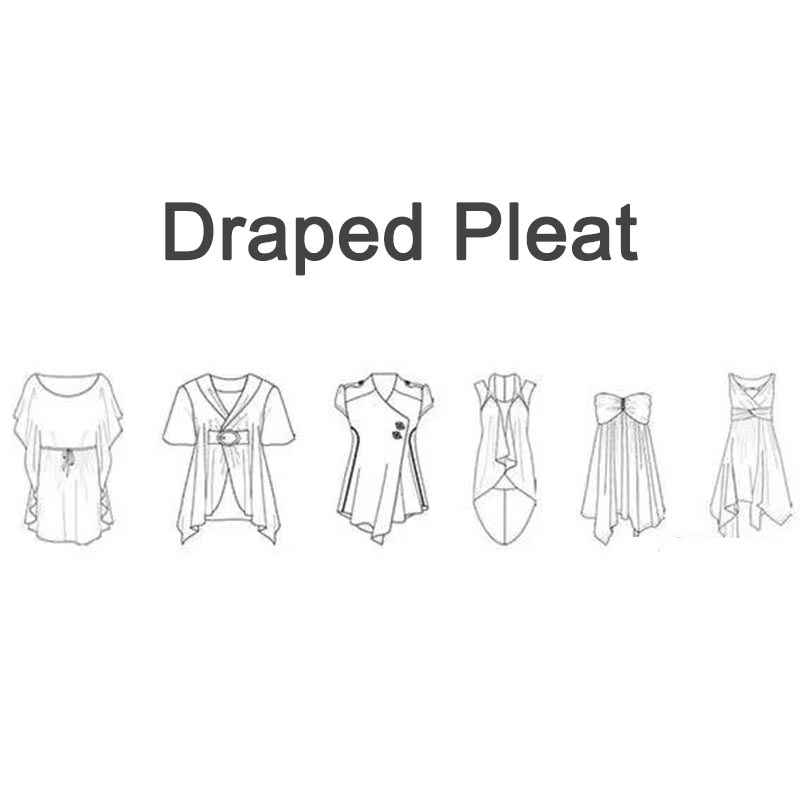

4.Draping pleats

Pendant pleats, also known as wave pleats, are pleated between two units (points and lines can be used as pleating units, or between two points, or between two lines, or between one point and one line) to form a dense and changing curve pleats, with waves, natural drops, soft and graceful, light and unfluttered texture. The draping pleats formed by fabric draping form natural draping pleats downward from the body's stress point, so that local expansion forms wave draping pleats, which can produce a rich and soft sense of rhythm and rhythm.

5. Common Sense Questions and answers about the crimp blind area

(1) What is the difference between manual crimping and machine crimping?

Machine pleating: It is the use of professional pleating machine for fabric pleating processing, generally like pleating, I-pleating, chaotic pleating, organ pleating and other regular pleating patterns belong to the machine pleating.

Manual crimping: Simply put, all the crimping styles that machines cannot do belong to the category of manual crimping. Like sun folds, straight folds, chicken scratches, etc. There are also some large-size pleats or I-pleats that exceed the maximum size of the machine pleats and are also pleated by hand.

Of course, there is also an important point, the cost of manual crimping is higher than the cost of machine crimping, because of low production efficiency and high process requirements.Hand crimping is mainly used in the garment industry.

(2) Cut first and crimp or crimp then cut?

This problem mainly depends on the factory requirements, usually cut pieces and then pleated.

However, the method of cutting and crimping in no order can only be used for special crimping styles, such as pleats, I-pleats, etc., for some manual pleats, it is not possible to cut pieces before crimping, such as: manual sun pleats, large-size pleats and I-pleats.

(3) What is the difference between garment pleating and cut pleating?

Most of the crimp styles are sheet crimp, and only the straight and random folds of manual crimp can be crimped for garment.

(4) How to place the crimp?

The general garment factory has its own version of the master, they by doing the pattern, know what to press the pleated requirements of what kind of code.

It is relatively difficult for the sun pleat to place the code, but it is necessary to explain that the cut of the sun pleat must be a fan type, and only need to flatten the sample when placing the code, do the pattern according to its size, and then cut the piece according to the paper pattern, and then send to the pleat.

Post time: Mar-27-2025